Less Energy, Less Material, More Packaging...

In conjunction with the progressive technology, metal, glass, plastics and cartoon packaging industries, the studies for reducing the weight of packages continue fast. The studies for reduction of weight of packaging materials have been successful with the help of technologies that make possible to produce materials with better physical properties.

Usage of lighter corrugated boards, especially in developed countries, is an important tendency in paper and cartoon packaging markets. In Europe, light weighted corrugated boards are used gradually more, because the capacity for light materials is being increased.

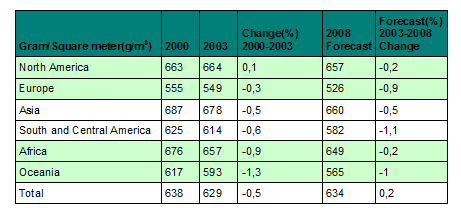

Table 1: Global Tendencies and Forecasts in corrugated board weights (2000-2008)

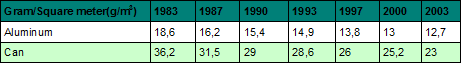

Similar tendencies in metal (bin and aluminium) beverage cans could also be observed. It has been reported that between the years of 1982 and 2003, the average weight of beverage can has been reduced to 23 gram from 36.2 gr. In the same period, the average weight of aliminium cans has been reduced to11,6 gram from 18.6 gr.

Table 2: The values of reducing weight in aliminium andcan beverage cans in Europe between the years of 1983 and 2003

The scale reducing application of aliminium folios in Europe folio industry has been drawing attention recently. It has been reported that since 1960, all over the world, aliminium based packages have been lightened by average %35.

Nowadays, plastic raw materials, have been becoming more important; and also they are the materials which require less package consumption per unit. Since 1970s, the amount of material used in garbage and shopping bags have been reduced by %50-60; thickness of stretch films have been reduced to 9 micron from 15 micron. The thickness of plastic bottle wall, have decreased %25 in recent 25 years.

Tetra Pak has declared that in a new developed package kind, the plastic thickness is decreased %30; however, it becomes more robust in its structure. Also, they have added that they have made 50000 ton saving in plastic raw material in one year and have used %17 less energy. But, the company has increased the cardboard amount by %3.5 in their packaging production.

Especially in flexible packaging materials, nowadays, scale reduction is an important concept. Films have been becoming thinner day by day. 10 years ago, 200 µm films were used in the production of heavy work bags, today these bags can be produced from 120 µm and thinner films.